|

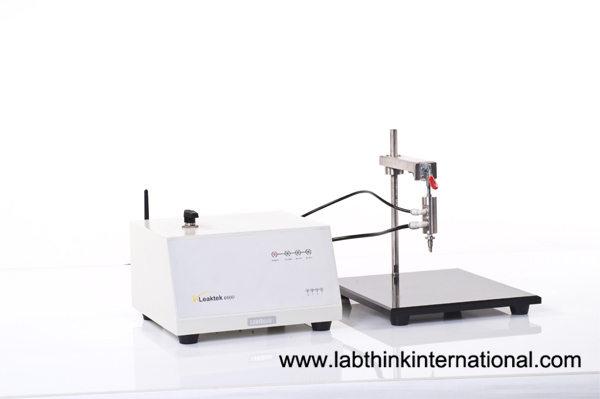

| i-GASATEK 6900 Package Headspace Analyzer |

i-GASATEK 6900 Package Headspace Analyzer for MAP Packages can be used with our advanced Online Data Management System for packaging testing, which comes with two versions to meet distinct needs of our clients: The Cloud Version & The Intranet Version

|

| i-GASATEK 6900 Package Headspace Analyzer |

Features:

1.Equipped with auto lifting stand which makes the whole testing process, including sample piercing and gas analyzing, completely automatic

2.The instrument can adjust test space according to the height of the sample to test

3.Multiple testing modes are available for the user

4.i-GASATEK 6900 Package Headspace Analyzer is designed with filtering function which prevents the powder content within specimen to block instrument

5.The sensors for O2 and CO2 are supplied by the world famous brand to ensure reliable overall product performance

6.i-GASATEK 6900 Package Headspace Analyzer for MAP Packages is equipped with four USB ports and dual Internet ports for convenient data transmission.

Technical Specification:

Test Gas:O<sub>2</sub> , CO<sub>2</sub>

O2 Test Range:0~100%

CO2 Test Range:0~100%

CO2 Test Accuracy:±2%

|

| i-GASATEK 6900 Package Headspace Analyzer |

Detailed information,pls contact Emily Wu at sales#labthinkinternational.com or Tel: (+1) 617-830-2190

Our website is:http://www.labthinkinternational.com/

Labthink International, Inc. is a global enterprise that provides professional quality control solutions for packaging materials and products. Our headquarters is based in Greater Boston, Massachusetts, well-known for being the hub of technological innovations. Our core businesses include the R&D of laboratory testing instruments, packaging testing and test data processing services. We are dedicated to providing integrated professional quality control solutions for packaging manufacturers, food and beverage producers, medical and pharmaceutical companies, and daily chemical and printing industries. Our Greater Boston headquarters combines functions of the North America sales division, the R&D center, the packaging testing laboratory, and the customer services center and administrations.

|

| Labthink International, Inc. |